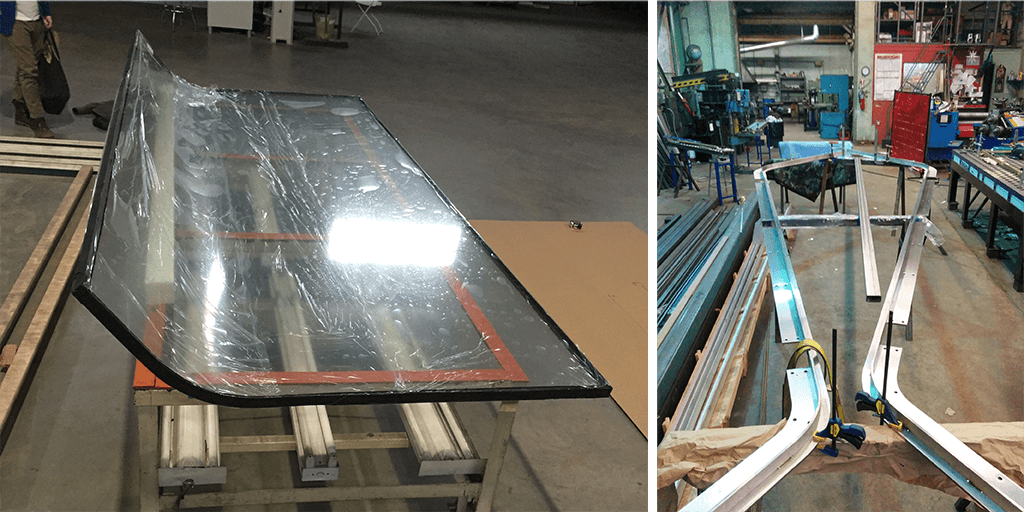

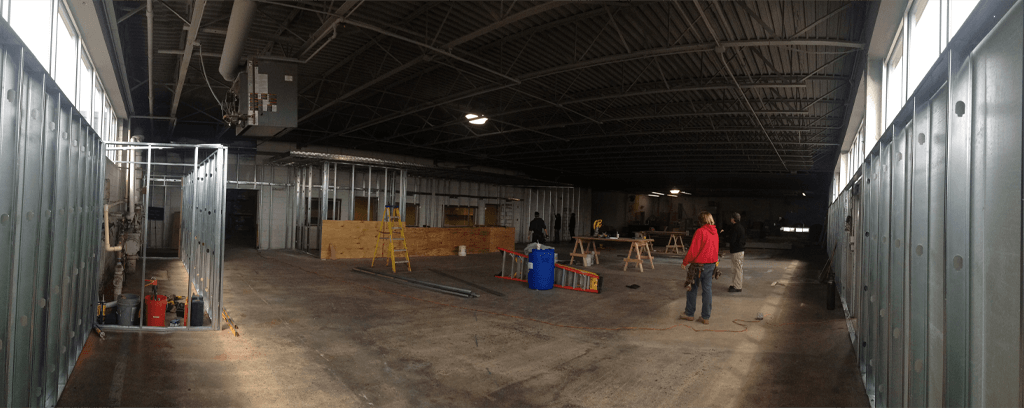

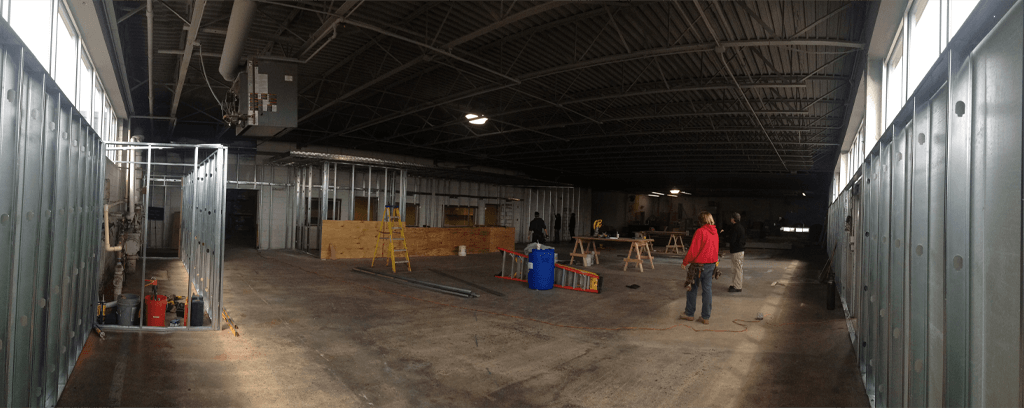

Flying Fish is an example of the design and construction process coming together to celebrate the iconography of a brand. Formulated through the crucible of a limited budget and short construction schedule, the design problem necessitated a timely and economic solution.

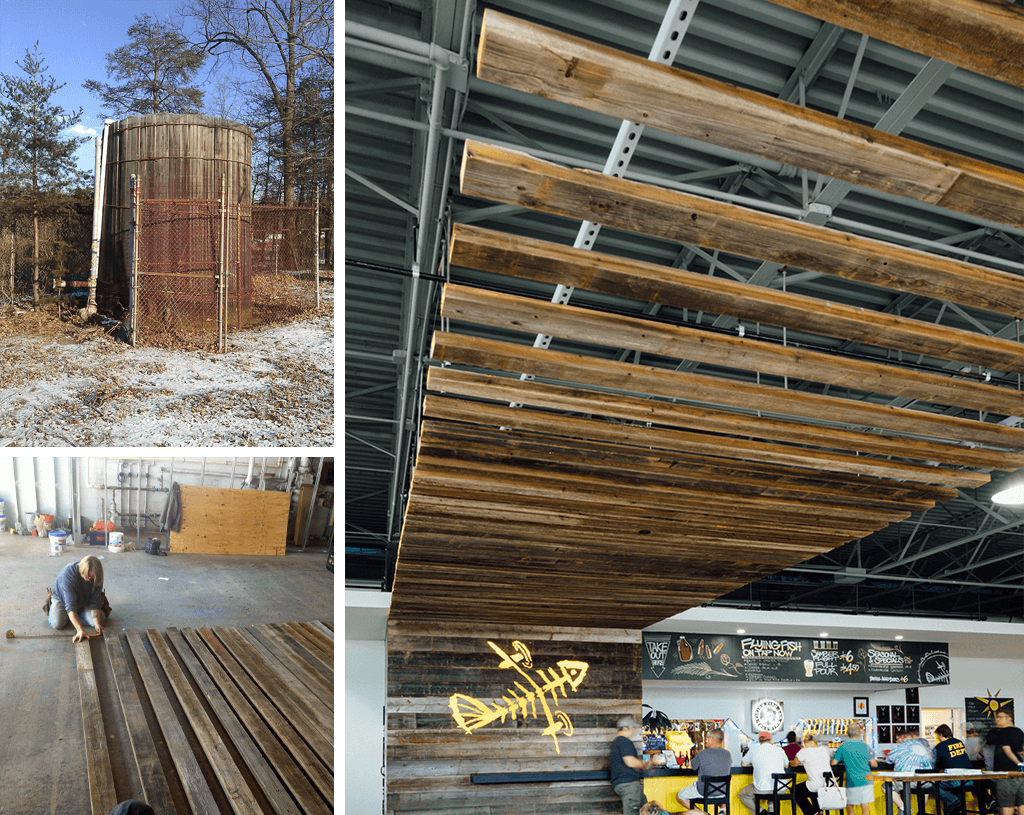

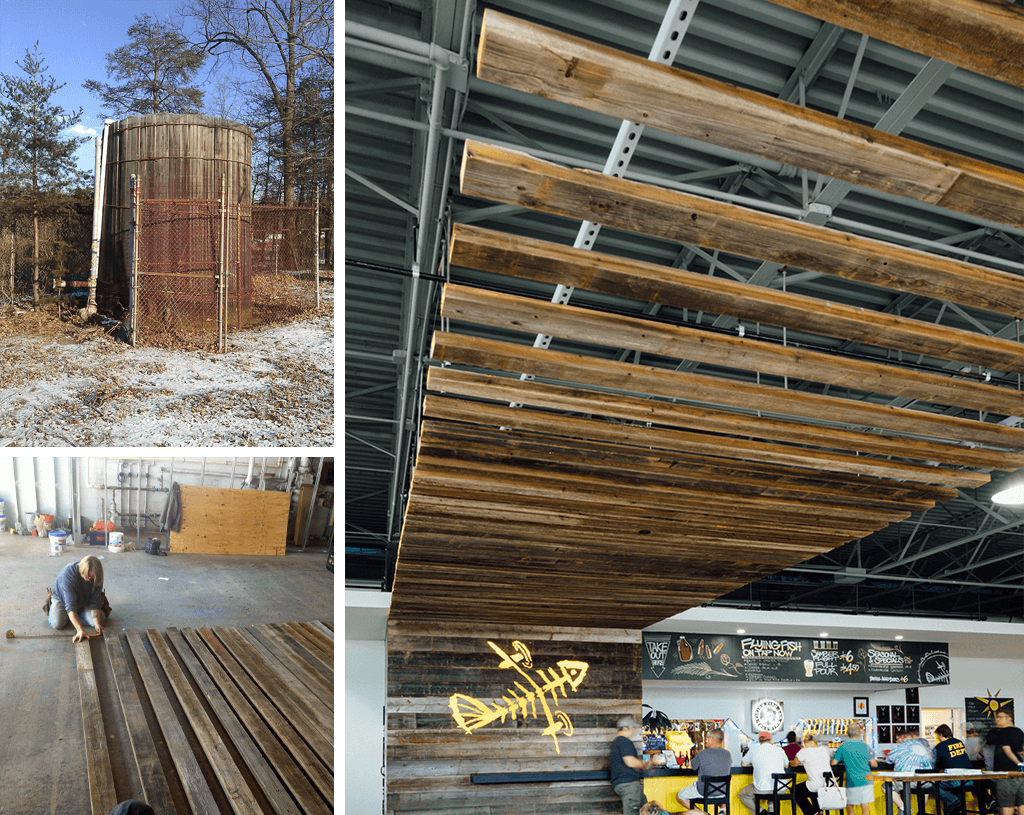

To keep costs in line with the limited budget, existing material sourcing was used for the 20-foot long exterior Flying Fish logo sculpture and the interior wall and scrim for the Tasting Room. Using the wood slats of an old onsite water tank, the material was salvaged to keep its aging patina, and finished to be appropriate for interior and exterior use.

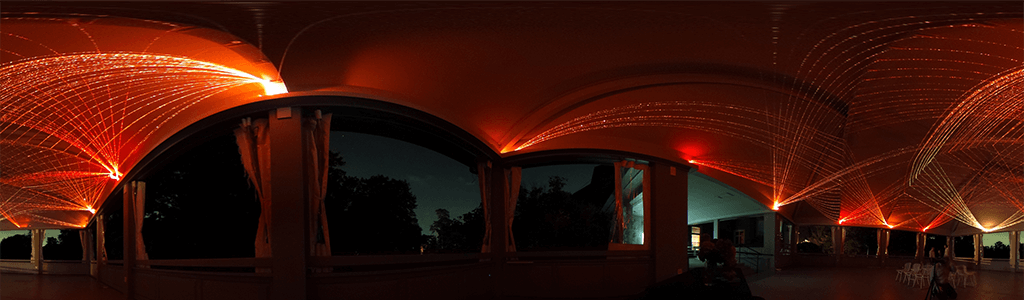

The interior wall and scrim ceiling were approached with the simplicity of using the natural geometric form of the slats, allowing for simple stacking. The opaque wood wall received a negative cutout of the Flying Fish logo done on a CNC mill. A lighting box was attached to the back of the wood wall to allow for backlighting. Floating pieces of the logo were connected to the backup to allow for the full expression of the logo. Less high tech but no less carefully considered, was the ceiling scrim. Placed with an increased spacing between slats, the pattern was reviewed on the floor, adjusted as desired, and lifted into place, offering a visual transition from the entrance of the tasting room to the solid of the logo wall.

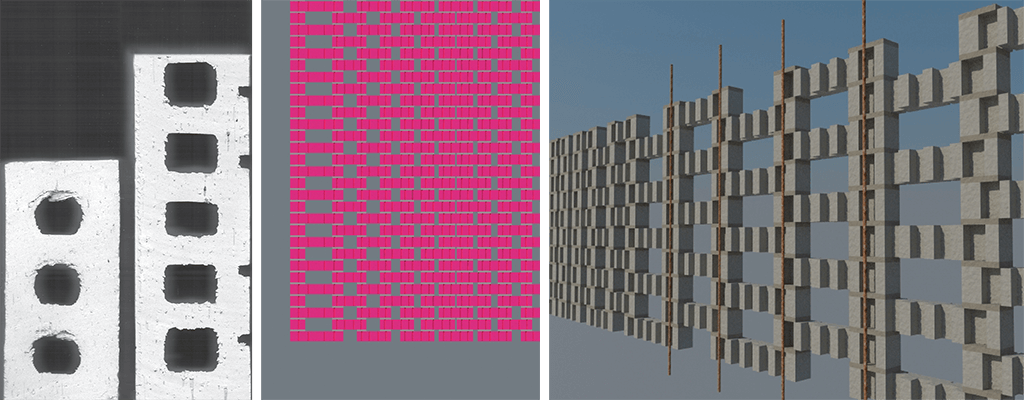

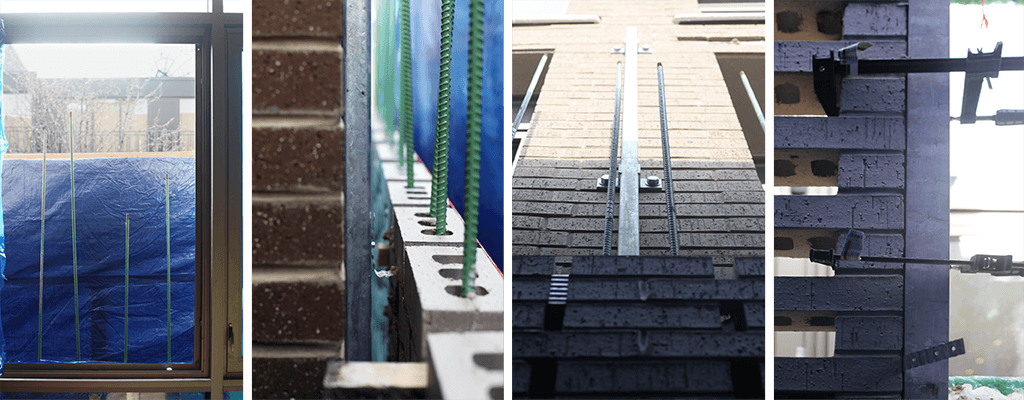

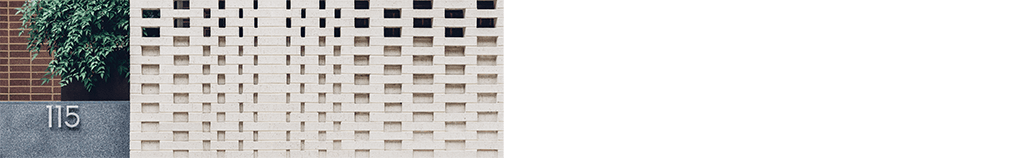

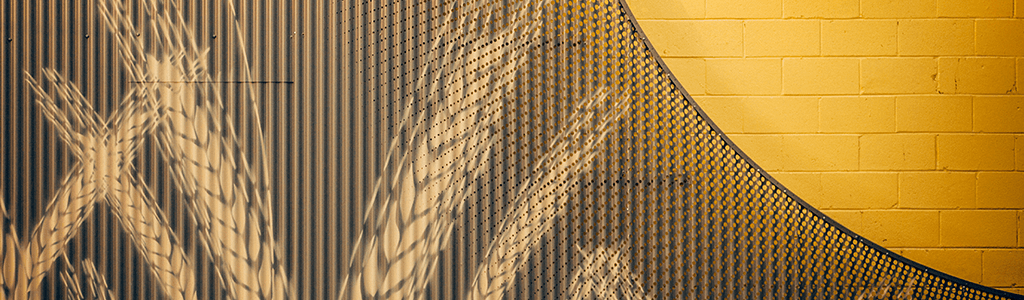

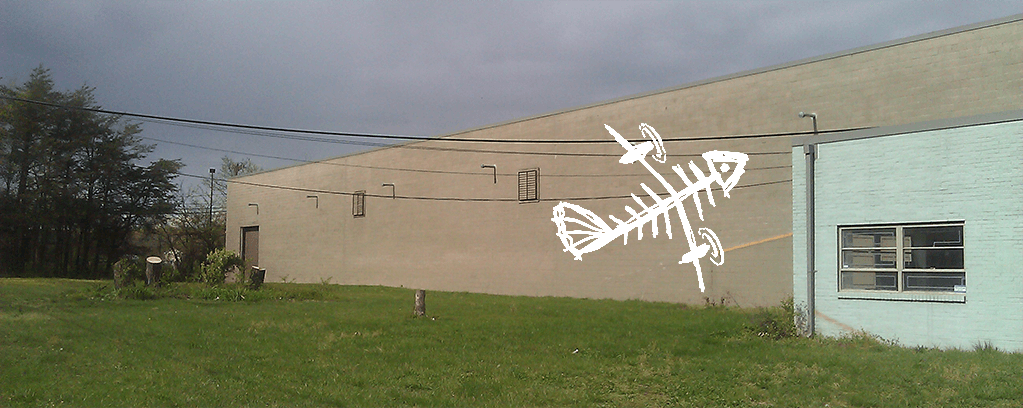

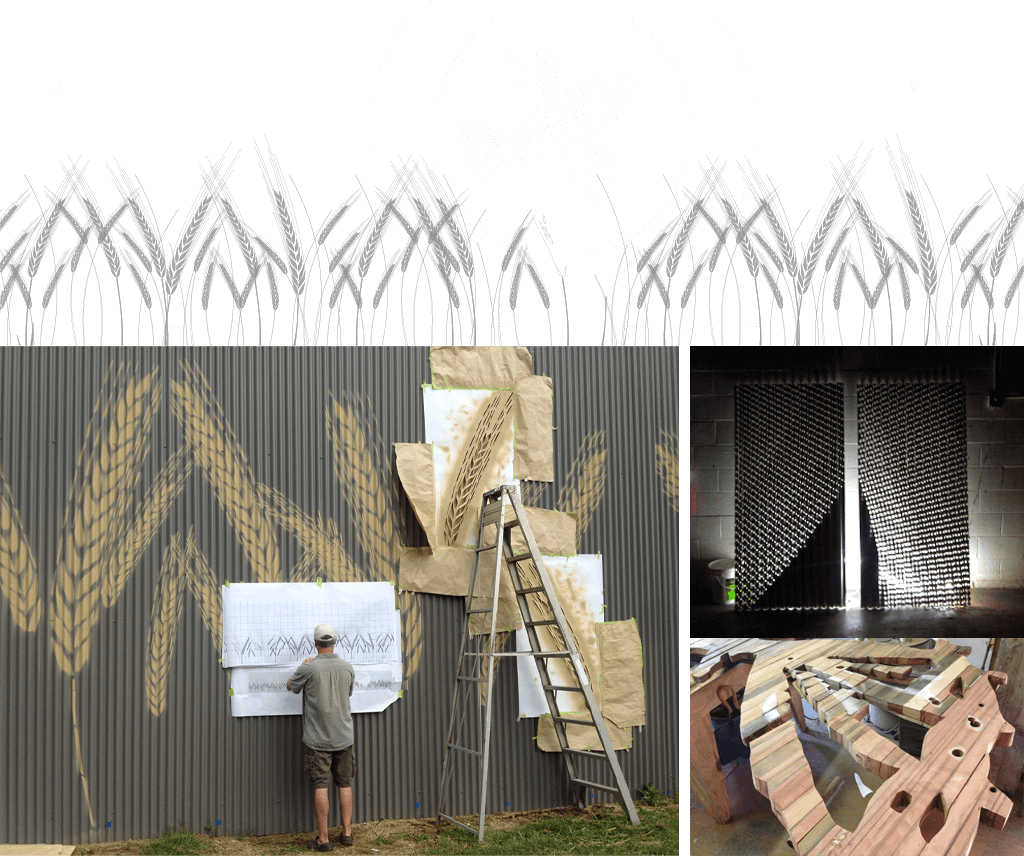

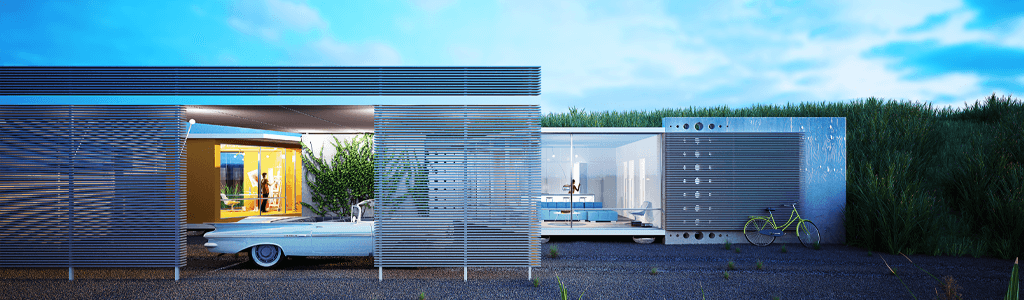

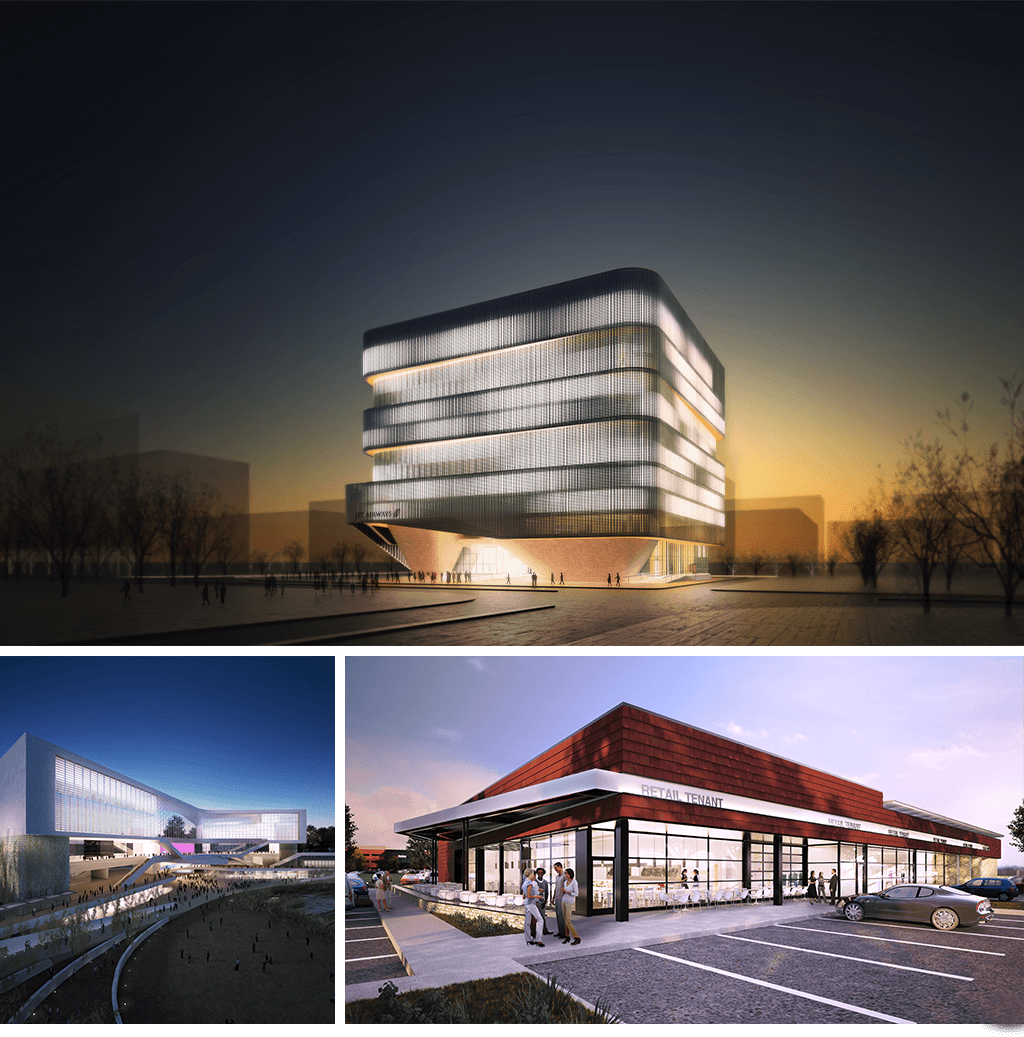

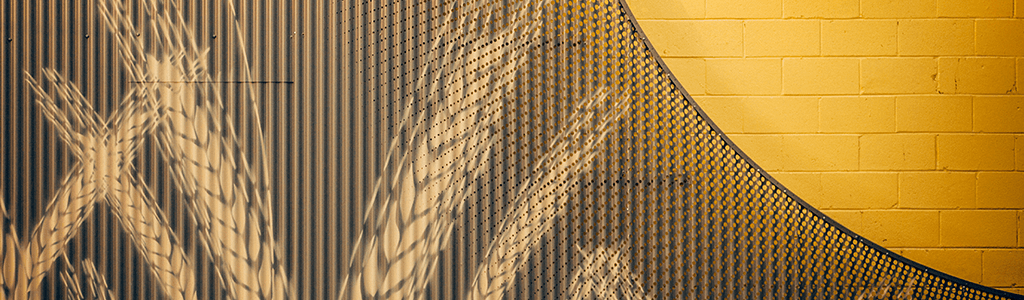

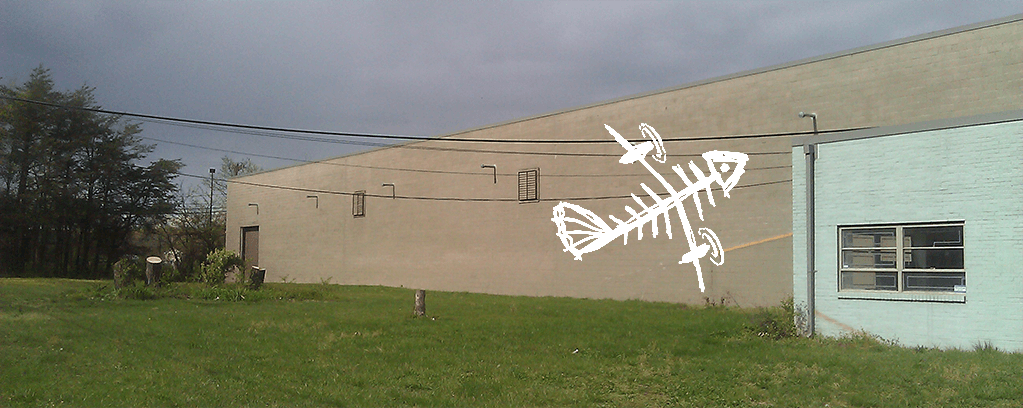

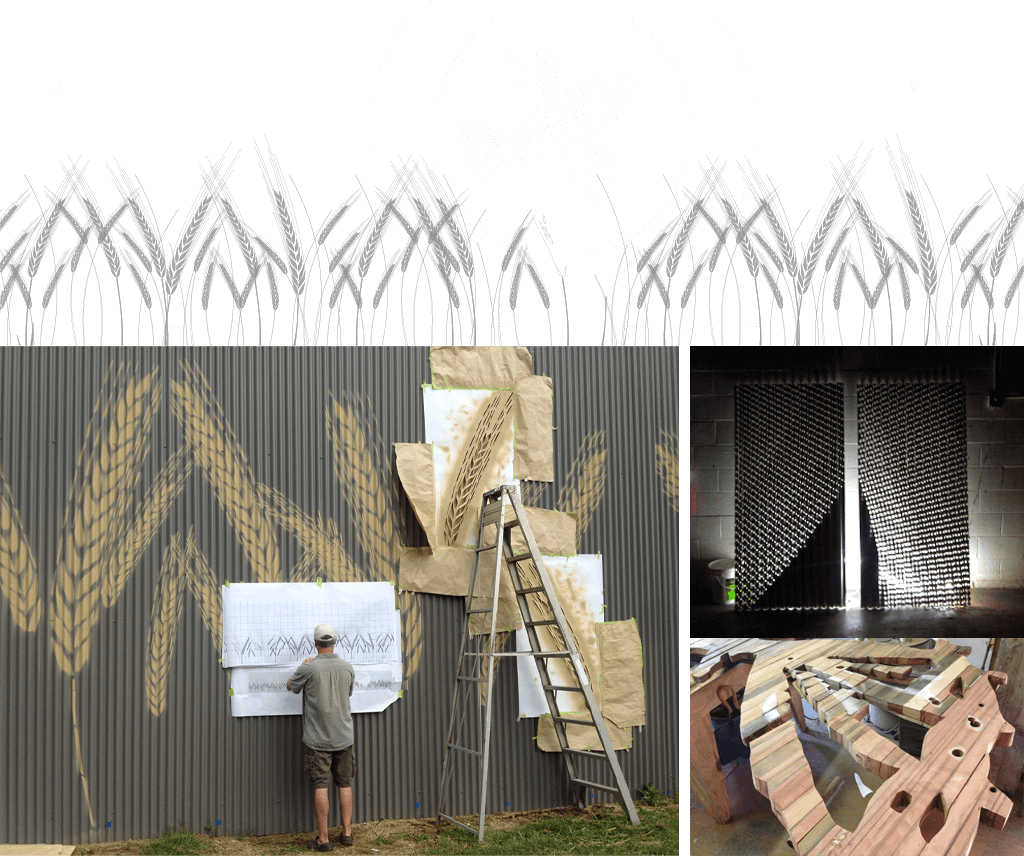

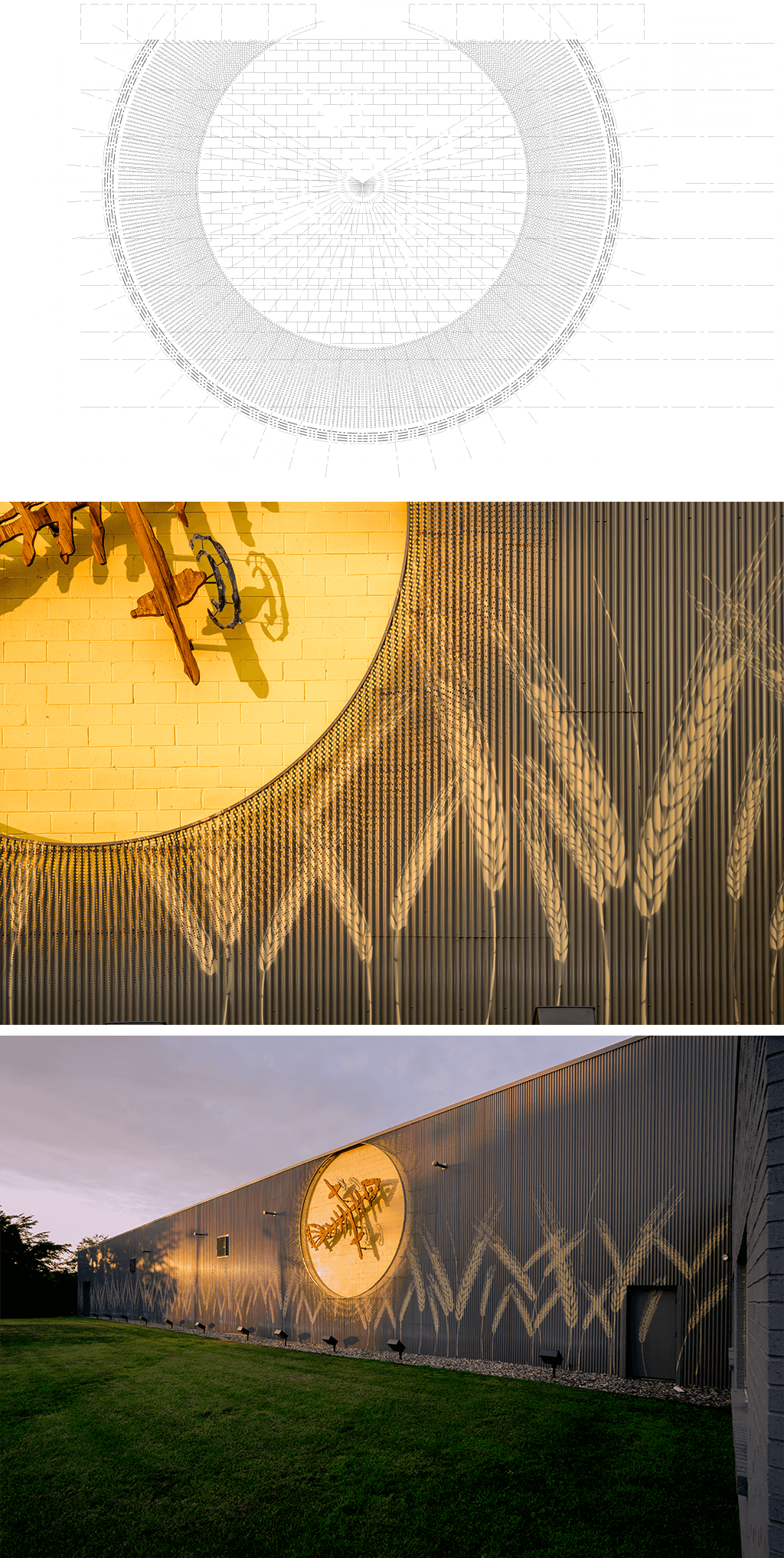

The exterior façade was a challenge of scale, material, and message. With a 300-foot long by 25-foot tall blank concrete block wall, Moto envisioned using the Iconography of Flying Fish’s logo at a scale that matched the monumental façade and the visibility of vehicular traffic of the street. Through an exercise in graphic design the image was translated into building. A motif of barley was proposed that visually supported the Flying Fish logo with a backdrop of a yellow sun.

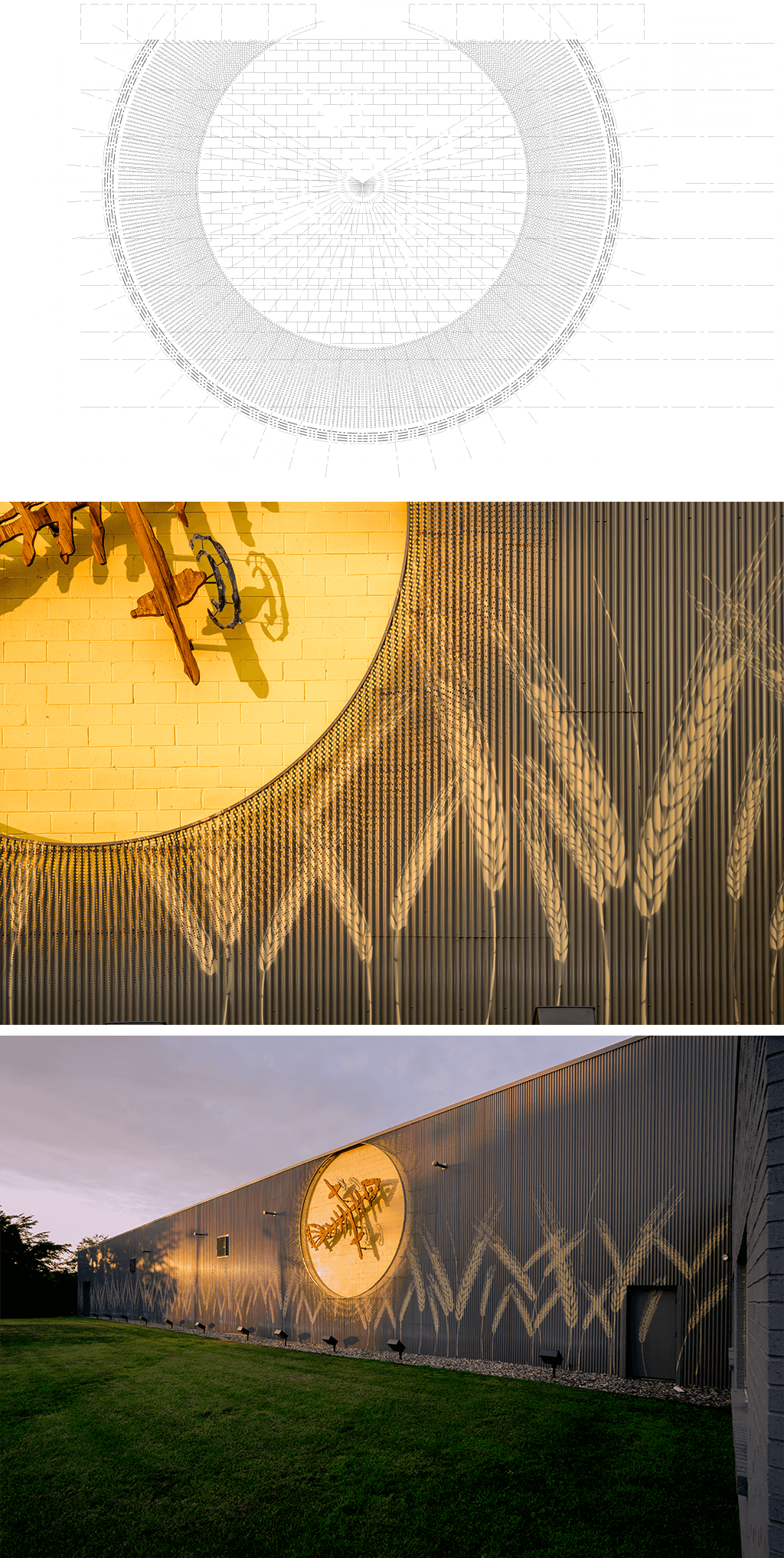

Materially the wall required a refined look while still meeting the limited budget. Moto used a corrugated metal panel, in which the panels were perforated into a radial pattern, to allow backlighting. The pattern was precut with a water jet, and through careful digital communication, Moto and the fabricators were able to coordinate the physical and visual result.

The motif of barley was airbrushed onto the surface of the metal panel by an artist who had experience with large scale graphics. In an exercise of one to one scale, Moto provided full-size templates that were used by the artist.

The realization of the composition of the multiple components could not be done without careful and precise negotiation between graphic articulation and construction. The above drawing shows the evidence of a careful discussion between multiple components and builders and the required technical representation to fulfill the potential of the design. The composition of the desired built product is embedded in the detail and richness of its representation. These types of drawings both give an insight into what the desired architectural result might look like but also the inner hidden workings of the final product. Ultimately making the drawings artifacts of their own.